MVH training notes

A few random notes taken during our loadbearing straw building training course with MVH.

General information about load-bearing strawbale houses

- Technique not suitable for timber cladding (battens must be added and fixed to the top and bottom timber plates for it to work): the straw is protected with plaster.

- In most cases, hybrid systems are used: a few posts and pre-frames help to support the roof loads.

- Foundations: nothing special to consider compared to other construction systems.

Material supply and performance

- When straw is used as a plaster base, the length of the fibres is crucial: the longer they are, the better the plaster will adhere. Furthermore, if they are perpendicular to the heat flow, the plaster will not adhere as well.

- Minimum density of bales for this technique: 90 kg/m3 on a dry basis. When the density exceeds 200 kg/m3, the insulating power begins to decrease.

- If a central channel baler is used, the fibres are more entangled and often denser and more compact, thus providing better insulation. The bales may be suitable for plastering, and even for laying on edge, BUT the fibres must be sufficiently long (minimum 5 cm).

- Bales shorter than 30 cm should never be used for construction.

- The string around the bales must be at least size 350, but it is better to use 250 (thicker).

- Storage is always on pallets (and even in a double row if the pallets are placed on grassy ground). There must be no contact between the bundles and any metal sheets or roofing protecting them (possible condensation). It may be advisable to have intermediate rows of pallets to keep them better stacked. Use a breathable tarpaulin.

- Check the elasticity of at least 8 small bales per batch, then one bale every 50.

- Set aside bales that are too elastic (type C1).

MISCELLANEOUS DETAILS:

- Barley straw is great for decoration when crushed (shiny reflections in the finishing coats).

- Straw dust contains a lot of silica, which is harmful to the lungs. Therefore, wear a mask if cutting a lot of it, especially indoors.

Manufacturing/bale selection

Central channel baler: better than a side channel baler for bales of uniform thickness.

Site management

Protection against rain and humidity

- Rain nets on frames (with support battens) can be used to protect the straw during construction. However, these nets only work well when they are positioned almost vertically, not horizontally. (see Propaille U1S2 presentation p.40)

- Multidirectional scaffolding, topped with a big top-style marquee, can also be used to cover the entire site (but these are difficult to find second-hand).

- To protect a wooden slab before it is waterproofed, a self-adhesive vapour barrier (rain barrier?) film can be used over its entire surface.

- If the bales are placed on a base, it must be covered with EPDM (capillary break) and an anti-termite barrier underneath.

- If building on a wooden slab, the capillary break and termite barrier must be installed between the masonry (concrete blocks, continuous footing, etc.) and the slab.

Termite protection

Drill 8 mm holes at an angle into the beams laid on concrete blocks, one hole every 5 cm along the thickness of the beam. Inject xylophene with a syringe (wear protective equipment: mask, gloves, goggles), fill each hole to the maximum, then hammer in wooden plugs.

Building design

- Limit: no more than 7 rows of small bales per wall.

- Avoid any load exceeding 600 kg/m² of wall.

- Maximum length of a wall made of small bales: 8 metres. If the length is greater, a partition wall or post is required, against the bale wall for bracing.

Layout

- Building corners: only lay whole bundles (which cross each other, are attached to the nearest bale, and are linked vertically with stakes along their entire height).

- Allow for 5 to 10% extra bales (count the gaps of doors and windows as if they were filled up).

Timber plates

- Dimensions of the roofplate installed during training: 14.5 x 4.5 cm (height x depth of wooden pieces: standard frame uprights). Allows for up to 2m of bay window-type opening in a wall.

- For a bay window wider than 2m, use 22cm studs instead of 14.5cm.

Design

- The roofplate must be made directly on top of the baseplate to ensure that they are exactly the same size.

- Dimensions of the pieces of wood: minimum 10 cm wide and 4 cm thick.

- Provide one spacer per strap passage.

- For a single-storey building with a mezzanine: provide for another baseplate above the intermediate wallplate to compress the strawbales on the upper floor.

- Chestnut, pine or Douglas fir: OK

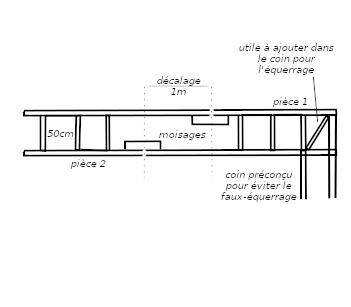

- Allow for 1 m offsets for assembly, AND avoid having a large load transfer at the assembly point (otherwise dislocation is possible)

- Ideally, make the corners from a single piece to avoid any misalignment, and add a diagonal piece to maintain the squareness (see diagram).

- To close the rail with maximum watertightness, adhesive sealant is ideal.

Insulation

- The baseplate must be fitted with incompressible insulation, such as cork. Low-grain Misapor can also be used. Avoid vermiculite (which retains moisture).

- To insulate the roofplate, avoid loose straw, which always protrudes between the uprights and makes it difficult to close the boxes. Other insulating materials (e.g. hemp shives or cork) are much more practical.

- Compriband seal or sealant is required under the baseplate to ensure airtightness

Water guard

Interior: minimum 45 mm

Wall assembly

Layout

3-4-5 method: start from a reference corner. Using a set square, mark 4 m on one side and approximately 3 m on another. Then measure the diagonal: it should be exactly 5 m.

Installing the dihedrals:

- first screw the stays into the dihedrals

- then into the rail

Installing the bales

- Each bale must be installed as perfectly as possible.

- Avoid filling holes between bales as much as possible. But if you have to choose, it is better to have holes to fill on the inside (because they add mass) than on the outside.

- NEVER force the bales onto the wall: this will cause the straw to protrude and the bale to bulge, especially after they are under pressure from the frame and roof.

- To help maintain a horizontal position, it's possible use levelling strings attached to the dihedrals.

- If you need a longer bale than the ‘standard' ones, it is better to keep the original bale and connect it to a small compact bale rather than adding straw pads to a long bale and then retying the strings (you will always lose density, and the bale will be too flexible).

- Connections between bales and frame uprights: avoid having straw pads that fall apart, especially when trimming with a hedge trimmer.

- Hedge trimmers are not ideal for finishing touches; it is better to use a brush cutter/string trimmer.

Pins

If using bamboo: it is better to use split pins (less risk of moisture/mould).

Not necessary, unless you often climb walls (unnecessary if you have scaffolding):

- time-consuming to install

- dangerous (for those pointing upwards, at the bottom rail)

- can interfere with bale compression (adds 1 or 2 cm per row)

- can shift the boots if poorly driven in

- ... but essential to use in the corners of walls

Box frames

- Ensure that the box frames are fitted with brackets to prevent them from warping.

- Never place bales above window box frames, as there is a risk of cracking during compression. Leave a space (for windows, anticipate settling by calculating the elasticity of the bales: e.g. if you think there will be 3 cm of compression everywhere, remove 3 cm from the section above the box frame).

- box-frame/joinery interface: leave 0.5 cm of space for insulation.

Pre-compression of bales

- To help pre-compress straw bales on the ground floor from the first floor: it is possible to place big bags filled with sand or water tanks on the bales, arranged evenly throughout, before attaching the straps.

- As long as the walls are not plastered, do not overload one wall more than another = Always control the level of the battens until the plastering is complete (props, temporary or permanent pieces of wood)

- Calculation of pre-compression (e.g. 7%, 7 cm): starting from the highest bale.

Straps

- 1 large ratchet strap per metre of wall

- 2 small straps (strapping bands) per bundle

- Avoid crossing the straps

- 1 rail spacer per small strap

- At least 1 diagonal strap in each corner of the wall.

- Apply initial compression with the straps, then a second time 24 hours later.

- Small straps: width 19 mm, woven strap made of polypropylene.

- Wide straps: 40 mm. (Instead of using truck straps, you can use 40 mm woven straps + appropriate ratchets, or do without wide straps and just use narrow straps)

- Alternate ratchets on the inside and outside of the wall to balance the compression

- When passing them under the bottom rail, consider the direction of the hooks once they are thrown over the wall: avoid having the hook facing the wall.

- Levelling the walls:

- You can attach a batten to the top rail, then measure the drop from the ground as compression occurs.

- with 2 people on either side of the wall; alternate small and large straps; coordinate: 1 or 2 ratchet notches

- to achieve the necessary compression (see Professional Rules table), measure the drop on all 4 sides, then calculate the average

- After compression, dry fill the holes between the bales (do not use earth: thermal bridge)

Roof plate and box frames

Technical notebook p21:

"The roofplate rests on the box frame after compression. It is therefore necessary to choose its height so that it does not interfere with the compression of the bales. If, during pre-compression, the roof plate does not rest on the subframe, incompressible wedges can be used to fill the gap between the two elements."

Electricity

- Run the conduits as much as possible in skirting boards at the bottom of the walls and/or in the partitions to avoid touching the straw.

- Use airtight boxes.

- Ideally, use a hole saw to cut holes for electrical boxes in dry plaster (rather than cutting them in the straw, where they will not be very aligned).

- It is also possible to use stakes driven into the straw and screw a box onto them, using sealant to ensure they are airtight.

Gables

It is not possible to have straw in load-bearing mode on the gables: pre-compressed boxes or framework. It is also possible to lay the bales on their sides.

Framework

- Small truss rafters are preferable to large traditional cut roofs for better load distribution on the roofplate.

- Once the roof plate has been installed, a slurry coat can be applied to the straw bales to protect them before installing the roof structure. However, DO NOT apply any plaster before the roof structure has been installed and the walls have been finally compressed.

Render

- Interior render dries much faster if the exterior render has not yet been applied.

- A layer of clay slurry on the bales, with holes filled in, is sufficient to provide initial protection for the facades before the plaster is applied.

- Use fibreglass mesh, facade mesh or linen mesh (not with lime). Embed it in the base coat to reinforce it.

- Clay slurry coat followed by a layer of lime-stabilised clay. Avoid applying quicklime directly to the first layer of earth, as it only provides physical adhesion, not chemical adhesion.

Joinery

- Wait until the interior plaster is dry before installing, for better ventilation.

- Wind-exposed façade: install the joinery frames as close as possible to the façade plane (better insulation).

- In all cases, install the joinery in the insulation plane to avoid any thermal bridges.

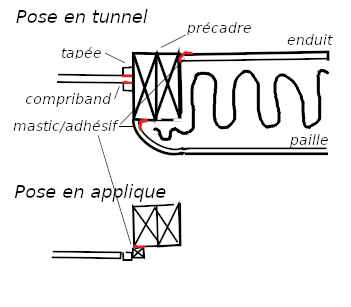

- Compriband seal to be installed on the exterior frame of the joinery. Do not skimp on the expense: its width must correspond to that of the joinery.

Window sills

- Made of wood or untreated terracotta (materials that absorb moisture): must have a slope of at least 20%

- For non-absorbent materials: at least 10% slope.

- If using an ‘industrial’ sill (aluminium, zinc, etc.): thinner, so it can be installed on wood wool insulation, carved to the desired slope.

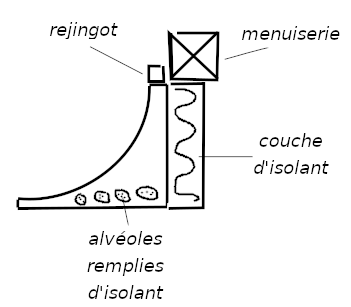

- Terracotta sill: fill the cells with insulation, otherwise there will be a large thermal bridge + add insulation behind the sill (see diagram)

Doors

Door thresholds: can be made of insulating mineral concrete (with vermiculite)

Air tightness

- Use frames and felt (more expensive when combined: felt can be purchased separately)

- Glue the felt part onto the joinery.

- Recommended brands: SIGA, ProClima

- An intermediate airtightness test can be carried out as a check before finishing the house.

- Recycled openings: often have joint problems, need to be replaced.

- Better sealing and easier installation when the joinery is surface-mounted. (see diagram)

Shutters

- Swing shutters: the shutter stop can be fixed to a piece of framework embedded in the straw, tied with string, then plastered onto the panel.

- BUT with the wind shaking the shutter, this stop will vibrate a lot and eventually break through the plaster... UNLESS this stop forms a clamp, which catches the shutter and prevents it from vibrating!

- Alternatively, you can use sliding shutters on rails; folding shutters (which fold inside the frame); or adjustable sunshades (the angle can be adjusted to control the amount of light)

Ventilation

- CMV often used in false ceilings or lost attics.

- Useful: humidity-controlled valves + extraction in wet rooms.

Miramon design tips

- Load-bearing beams for the mezzanine: 25x8 section (if there are ties between posts and beams, the section can be reduced)

- Layout: ensure there is at least 1.5 bale between joinery (= if 90cm wide bales, 135cm)

- Lower partitions: these will reinforce the walls. However, they need to be braced (Fermacell, OSB, etc.) + half-timbering

- Terrace: for the first wooden board near the walls, use a grid instead of a board to ensure water evacuation + ensure there is a proper baseplate (minimum 20 mm water guard)

- Check the opening of the stairwell so we don't bump our head (half steps possible)

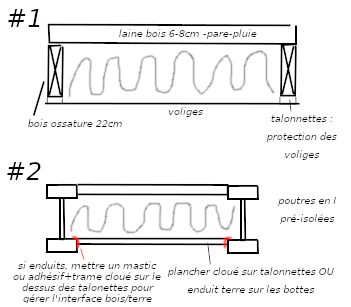

- Strawbale roof insulation: this can be done with wooden frame studs (22 cm) or I-beams (see diagrams); and add clay plaster underneath the bales to add more thermal mass

- Air supply for the stove can pass under or inside the wooden slab, from the greenhouse + a direct air supply to the interior of the house

- Rafters: use 6x8 (or even 15x8?) for the eaves

- Have several small trusses for the roof structure rather than 2-3 large ones, in order to better distribute the weight of the roof on the top plate

- 20x20cm post in the centre of the room to support the mezzanine and the ridge + need for load support under the wooden slab at this location. Could be a single huge post in one piece with notches for mezzanine support OR two assembled posts.

-

- 1 post for the ridge in each gable.